Sipotek is a professional china automated optical inspection machine manufacturers located in shenzhen city,major products including visual inspection machine and automated optical inspection (AOI) machine.

Even though there have been technological advancements in inspection techniques, visual inspection technique is the leading and most important testing method.

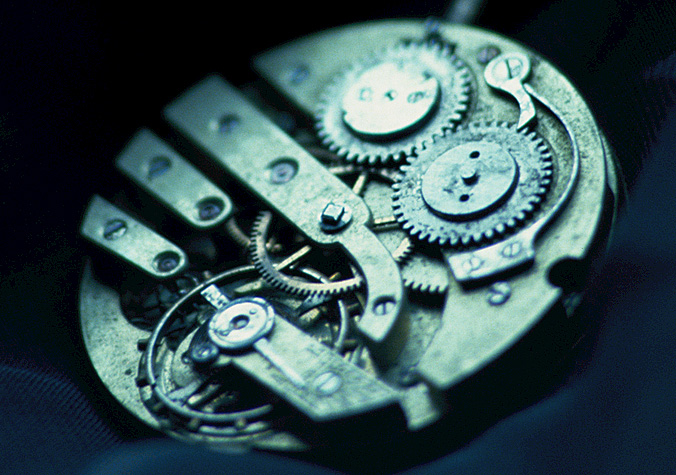

A visual inspection system is designed to expose any kind of imperfection on parts: cracks, cuts, stains, porosity, scratches, and imperfections. The ultimate goal as such is to help the customer produce the nearly perfect parts: products that will allow them perform and compete well in an increasingly demanding market.

One of the most recognized and effective method for non-destructive testing is visual investigation. The visual test requires that there is adequate light from the test surface and a good view of the analyzer. To pass a visual examination however, it needs special attention because it demands adequate training (knowledge of the procedure and element, foreseeable administrative conditions, archiving, recognition criteria) and has its own tools and equipment.

Likewise, it is a fact that any imperfection found at the end of other techniques should be justified by visual inspection. The visual test can be accompanied by remote visual tests, direct visual tests, and translucent visual tests.

Visual inspection can be used to explore the interior and exterior surfaces of assorted equipment, including storage tanks, pressure vessels, piping and other tools. Although there have been advances in other NDE innovations, visual inspection will likely remain the major strategy for investigation for many field applications. As new optical and mechanical guides become available, the consistent quality of visual inspection techniques will rise to far adequate levels.

Visual inspection of non-destructive tests is an important technique usually ignored. For this purpose, evaluators should begin with the NGS sector. For example, a visual assessment of an operational structure can often reveal obvious emission areas, such as excessive pulsations, infiltrations, rust or misalignment. This survey is a highly specialized practice and can be used to identify territories that require an additional application of NDT.

Training in visual inspection, while it is easy to learn, requires skill. By learning visual tests, you will be well prepared for any area dependent on visual control techniques. Non-destructive tests, including methods of visual inspection, are a convincing method for conducting essential non-destructive tests. Enjoy the benefits of non-destructive testing tips and learn the visual exam technique immediately!

The course is designed to meet the requirements of industrial qualification for the visual examination. The preparation covers the essential theoretical elements, the testing standards, the operation and the institutionalization of the equipment, the working strategies, the safety, the material procedures, the appropriate determinations, the codes and the composite indications used by the company and understanding signaling and preparation of the laboratory. The course meets the preparation time needed for the Level 1 and Level 2 visual inspection certification.

After spending a few years in functional industries, heavy industry and Ehler was chosen as vice president of RISC’s external services. Subsequently, Ehler adopted non-destructive tests that allowed him to acquire a thorough knowledge of practical functions in a multiplicity of service situations and environments. Mr. Ehler, as a TXNDT trainer, is committed to providing his students with the ideal curriculum for each proposed training course.

To learn how a visual inspection machine can automate the production process, one can visit the website https://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

没有评论:

发表评论