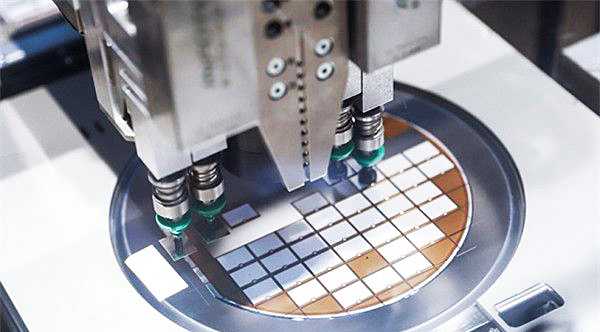

Automate Optical inspection (AOI)of finished products has always been one of the basic and most recognized applications of quality control in any industry. This inspection remains largely a manual process conducted by QC operators, and thus faces considerable limitations that make it unreliable.Therefore, it is necessary to make the inspection automated for better efficiency. Sipotek has the technology and skills to build automatic inspection system which is tailored to your products’ need or production flow.

Machine vision is very important during the automate inspection process, therefore the camera, the lighting conditions, and the inspection software system are quite indispensable for a good inspection machine.

Sipotek self-design software system which is a powerful and easy-to-use machine vision software for automated inspection, high accuracy measurement and data collection, both in process and off-line. It can be used to carry out a wide range of automated tasks including:

• Image Capture, Manipulation and Processing

• Image Registration and Alignment

• Pattern Matching

• Inspection and Verification

• High-Accuracy Measurement

• Image Analysis

• Optical Character Recognition & Verification

• Defect Detection

• Assembly Verification

• Color Verification and Analysis

• Present/Absence Detection

• Object Counting & Sizing

• Documentation

• Data and Statistics Collection

• Pass / Fail Testing

And etc.

• Image Capture, Manipulation and Processing

• Image Registration and Alignment

• Pattern Matching

• Inspection and Verification

• High-Accuracy Measurement

• Image Analysis

• Optical Character Recognition & Verification

• Defect Detection

• Assembly Verification

• Color Verification and Analysis

• Present/Absence Detection

• Object Counting & Sizing

• Documentation

• Data and Statistics Collection

• Pass / Fail Testing

And etc.

One of the things that we do especially well is that we customize our vision inspection equipment – quickly & cost-effectively – to solve customers’ applications. We have worked with end users and Original Equipment Manufacturers to solve their quality problems.

We design different inspection solutions according to different products various from online and offline detection. Most importantly the machine inspection system can save manufacturers more time and cost from labor inspection at the same time improve quality control and working efficiency. Sipotek has formed a business work flow from customer negotiation to after-sold service. The basic is to understand customers’ inspection needs from dimensional or appearance defects. After all concerns are discussed with solution, the inspection system and machine can be put into production and then reach to customer’s end.

Using the powerful and easy-to-use Sipotek machine vision software package, these systems have a simple and intuitive interface and include a wide range of fully-integrated tools for imaging, automated optical inspection (AOI) and automated measurements, qualitative Pass/Fail inspection, pattern matching, Optical Character Recognition & Optical Character Verification (i.e. OCR & OCV), statistics, data basing, reporting and much, much more!

We offer Sipotek users continuing support through our renewable Annual Support and Update Program, which entitles you to receive free updates for a full year membership as well as unlimited support by telephone, fax, and e-mail.

For more information about AOI systems and machines, visit https://www.sipotek.net/

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Website: https://www.sipotek.net

没有评论:

发表评论