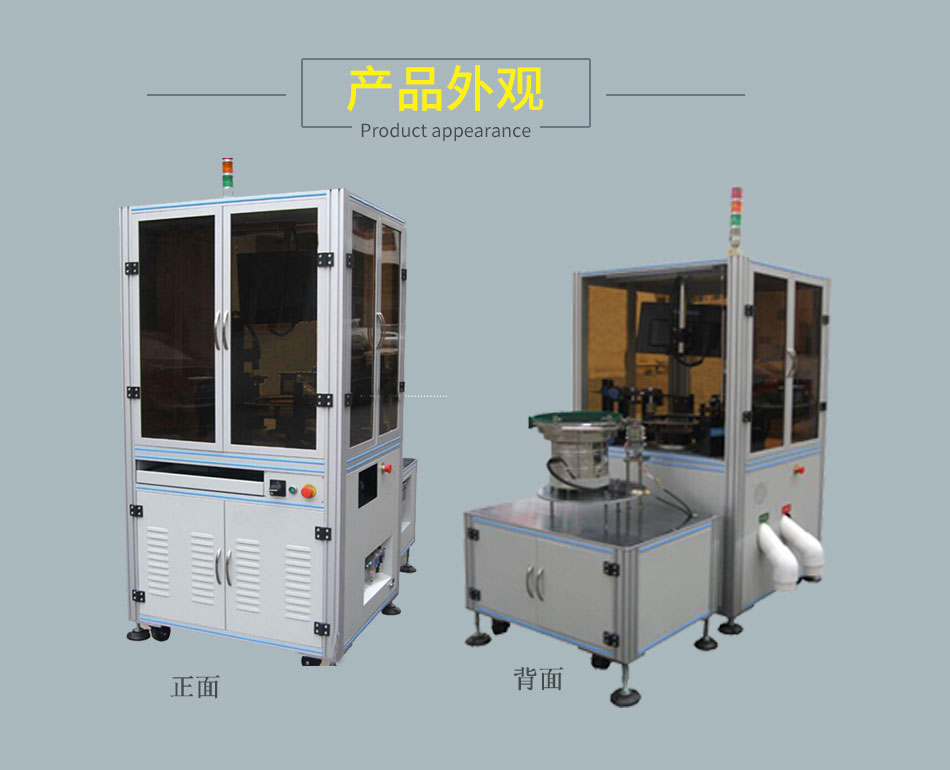

Sipotek is a professional china automated optical inspection machine manufacturers located in shenzhen city,major products including visual inspection machine and automated optical inspection (AOI) machine.

Automated or automatic optical inspection, AOI, is a fundamental technique used in the manufacture and testing of electronic printed circuit boards, PCBs. The automatic optical inspection, AOI, allows a quick and accurate inspection of electronic component assemblies and in particular the PCB to ensure that the quality of the product leave the production line is high, and the elements are made correctly and without manufacturing flaws.

The Need for AOI, automatic optical inspection.

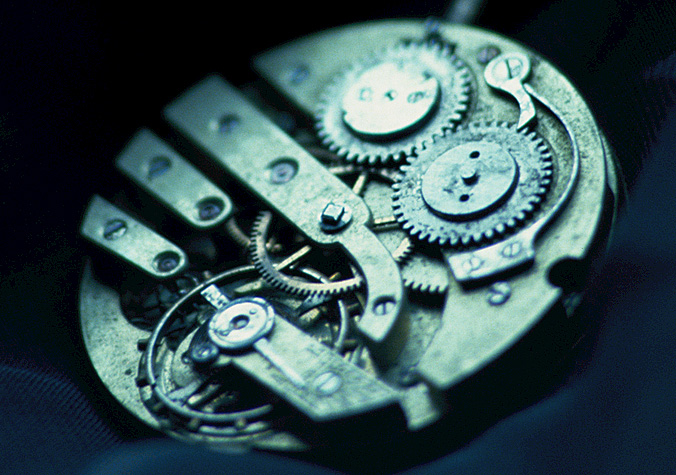

In spite the important advancements that have been made, modern circuits are much more complicated than panels were a few years ago. The introduction of surface mount technology and further size reductions mean that the plates are particularly compact. Even relatively average boards have thousands of soldered joints, and that’s where most problems are found.

This rise in the complexity of circuit boards also means that manual inspection is not an efficient option nowadays. Even when it was an accepted approach, it was found not to be particularly effective, since the inspectors soon got tired and the incorrect and incorrect construction was easily omitted. As the market now requires high volume and high quality products to be marketed very quickly, very reliable and fast methods are needed to ensure product quality remains high. AOI, automatic optical inspection, is an essential tool in an integrated electronic test strategy that ensures that costs are kept as low as possible, detecting failures at the beginning of the production line.

One solution to this is to make use an automated or automated optical inspection machine. Automated optical inspection machines can be placed on the production line immediately after the soldering process. In this way, they can be used to detect problems early in the production process. This has several advantages. Because faults cost more to repair them throughout the production process, this is obviously the best place to find flaws. In addition, welding and assembly process problems can be seen at the beginning of the production process and the information used to quickly feed back into the initial stages. In this way, a quick response can ensure that problems are recognized quickly and corrected before many tables are created with the same problem.

AOI, automatic optical inspection foundations

Automatic optical inspection systems, AOI, use visual methods to monitor defects in printed circuit boards. They can detect a variety of defects in surface features such as lumps, scratches and blemishes, as well as more familiar dimensional defects such as shorts opening and thinning welding. They may also detect incorrect components, missing components, and improperly placed components. As such, they are able to perform all the visual checks made earlier by manual operators and much more quickly and accurately.

This is achieved by visually scanning the surface of the plate. The place is illuminated by various light sources and one or more HD cameras are used. In this way, the AOI machine can construct an image of the board.

In automated optical inspection, the AOI system uses the captured image that is processed and then compares it with the machine’s knowledge of how the plate should be. Using this comparison, the AOI system can detect and highlight any suspected area or defect.

For more about automated optical inspection manufacturers,you can pay a visit to https://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net