The visual inspection machines designed by the Shenzhen Sipotek Technology Co., Ltd can automatically detect defects in a product and help maintain the product quality.

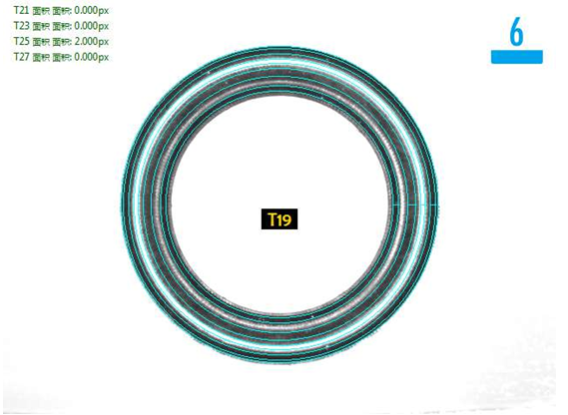

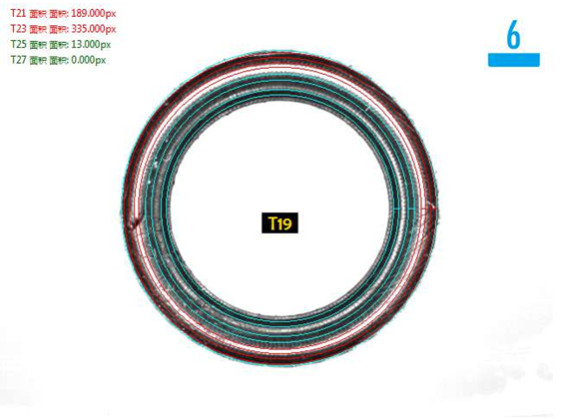

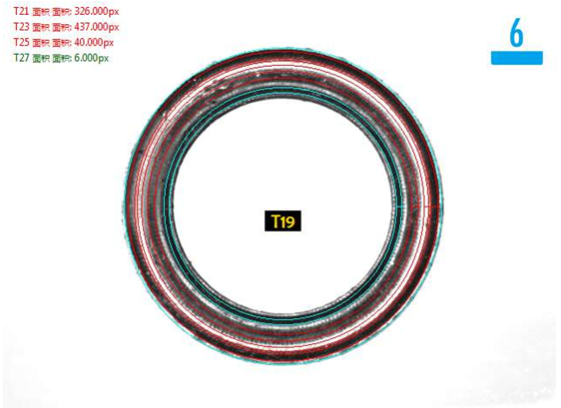

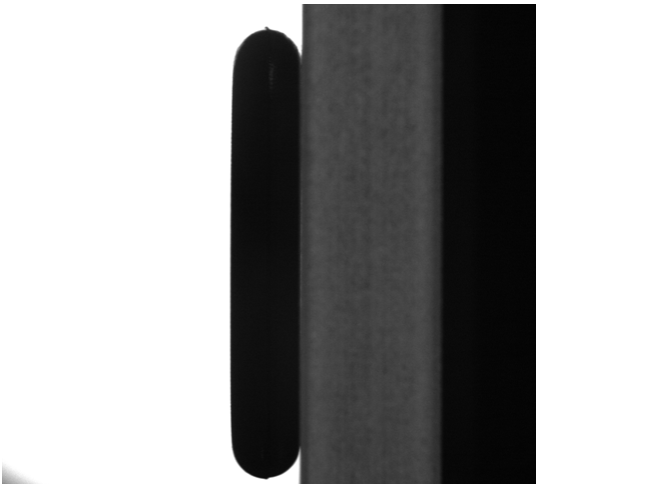

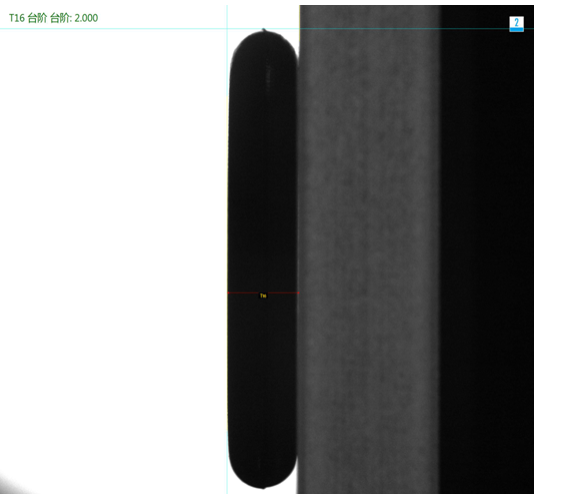

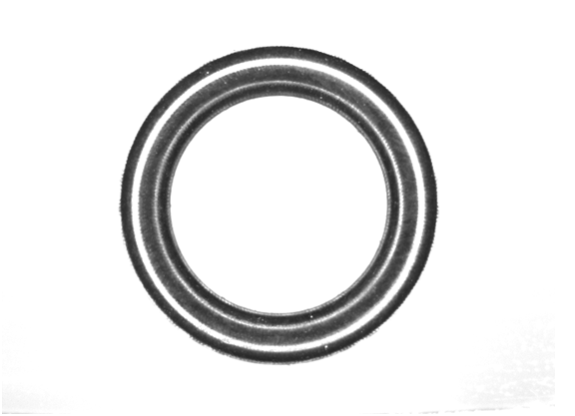

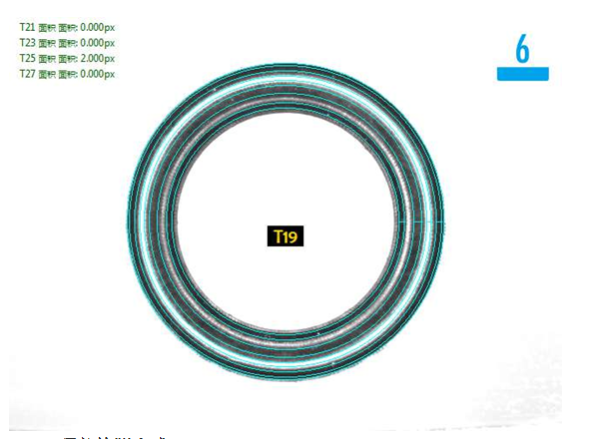

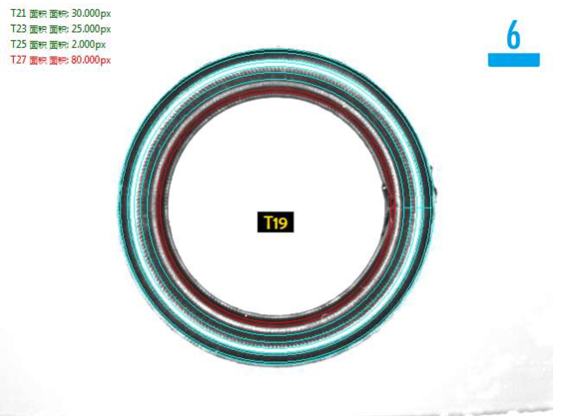

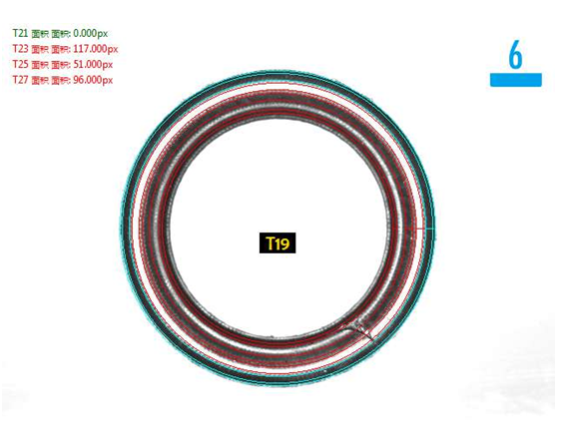

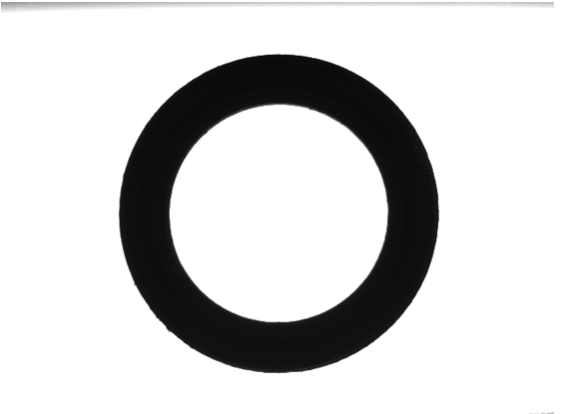

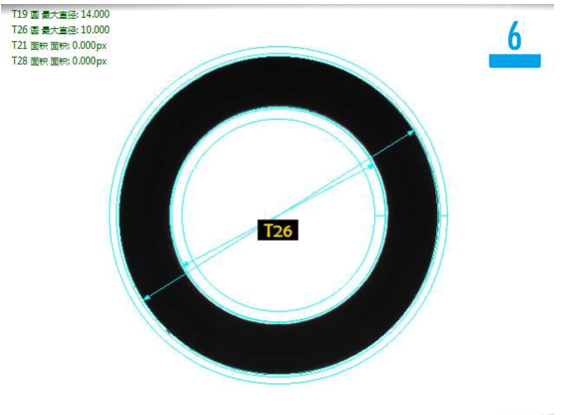

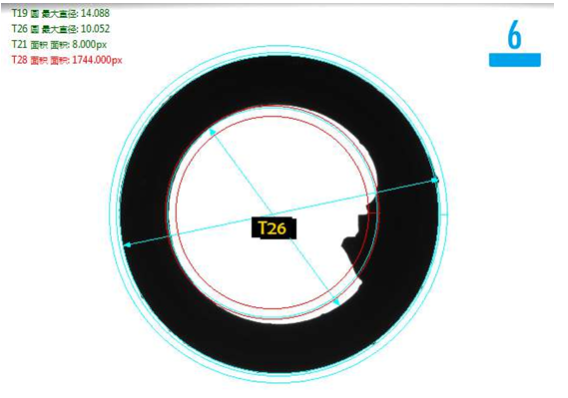

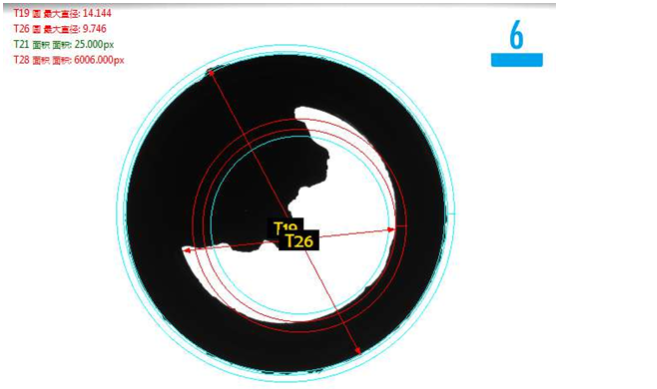

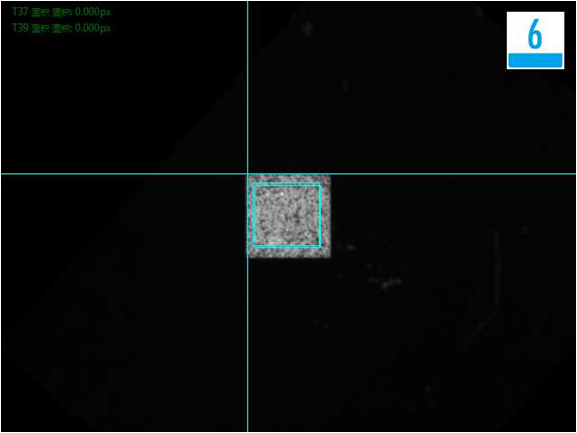

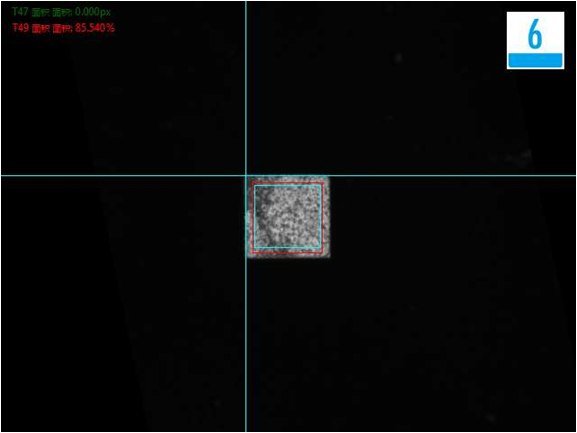

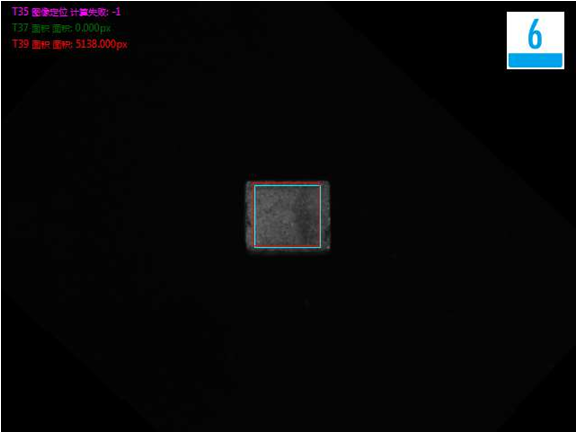

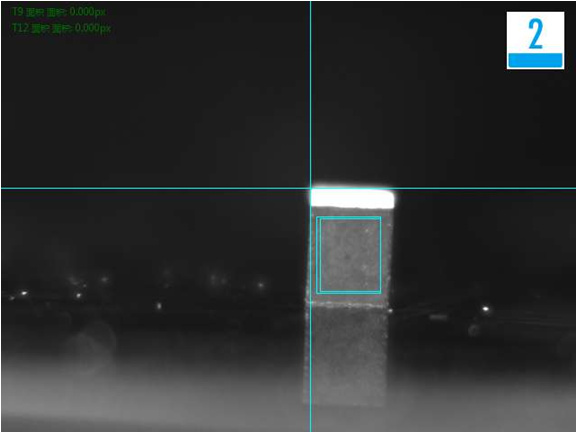

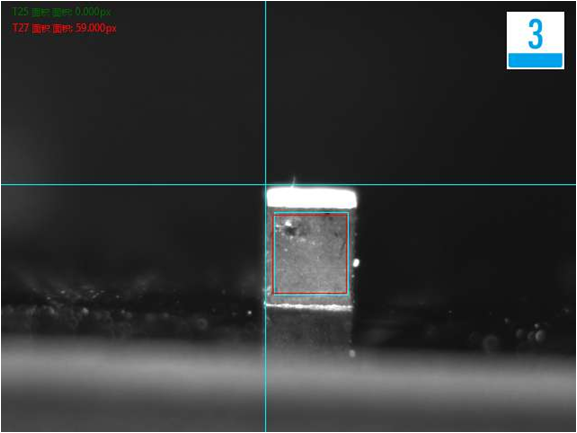

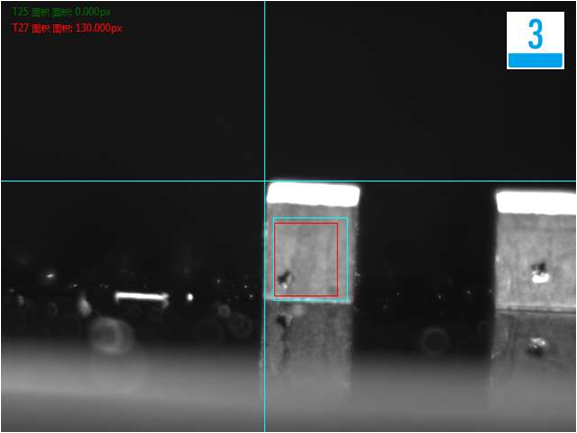

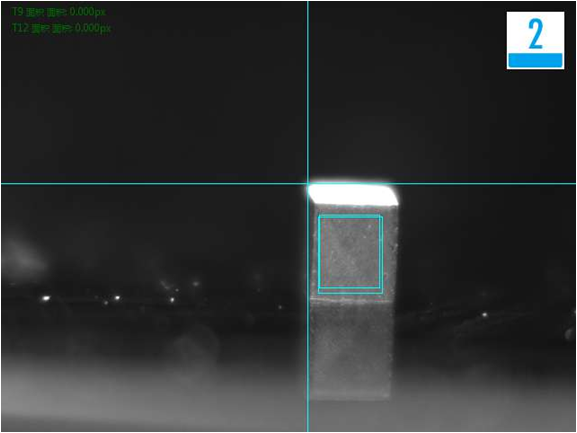

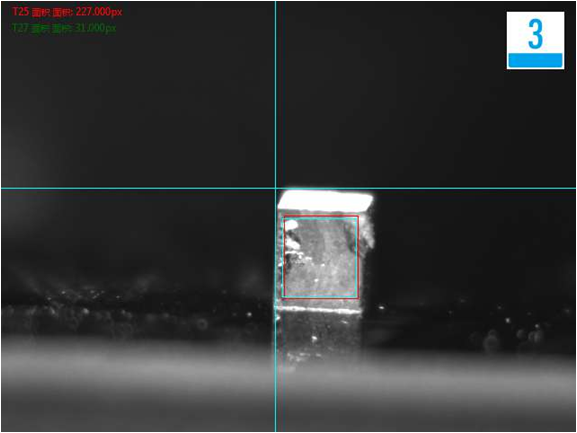

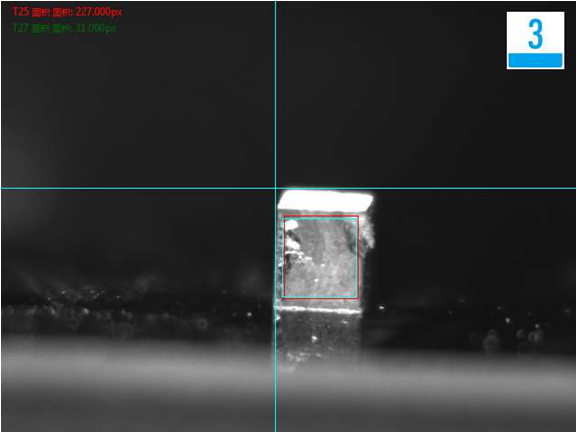

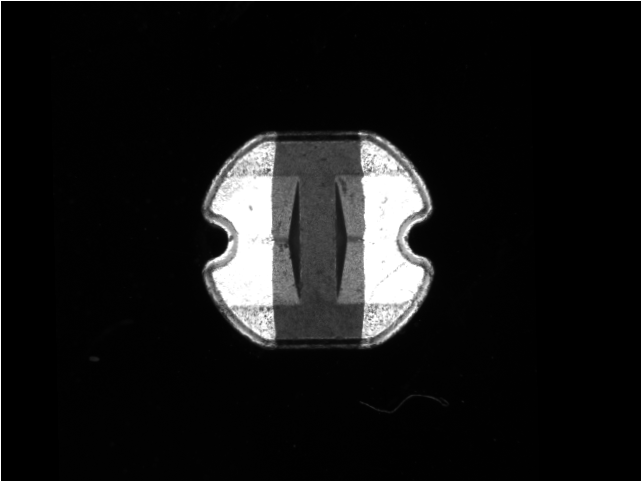

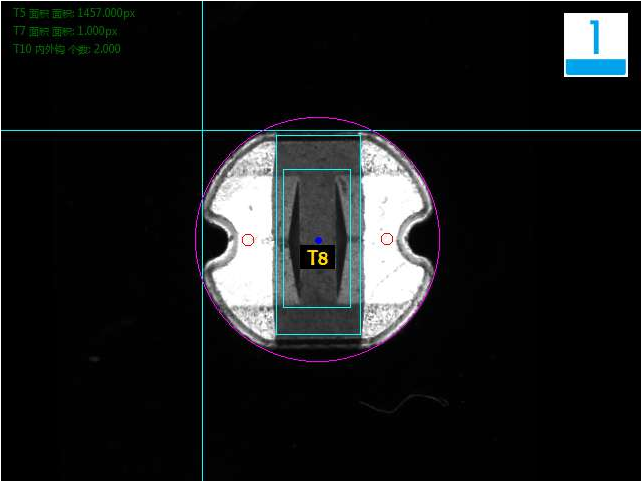

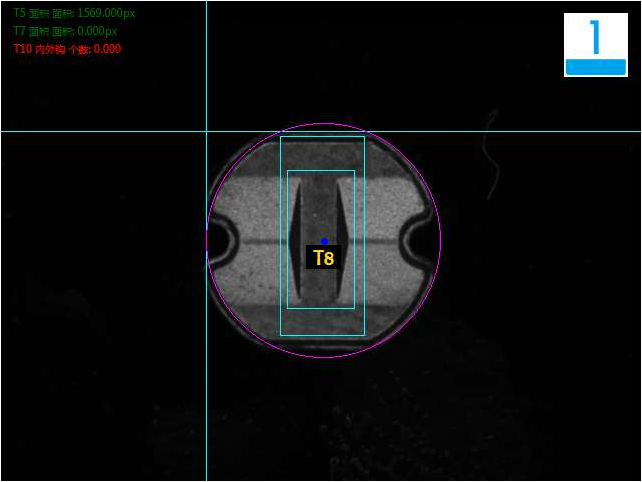

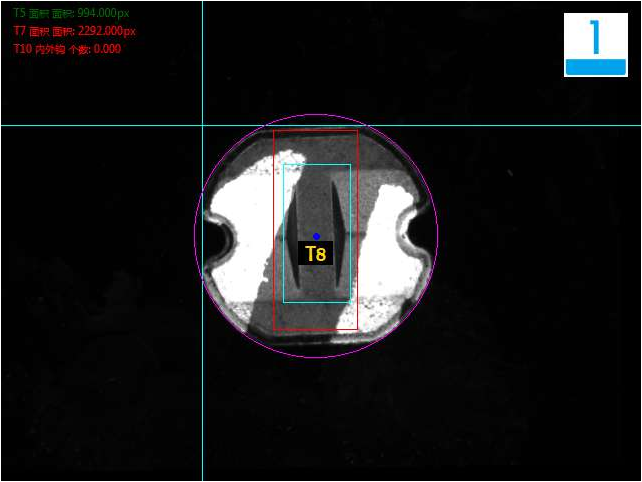

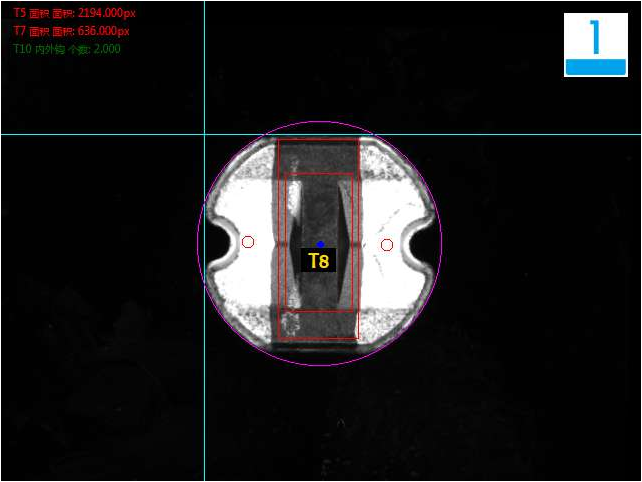

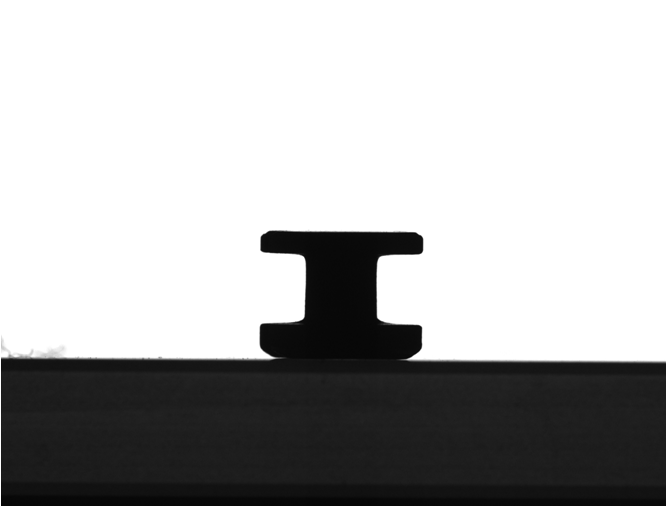

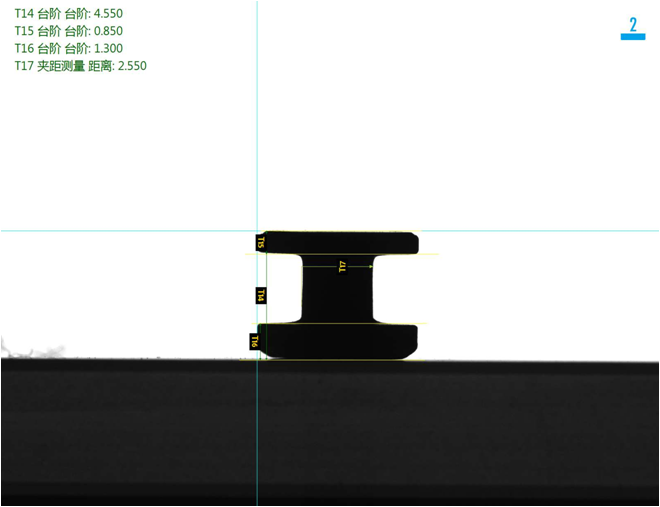

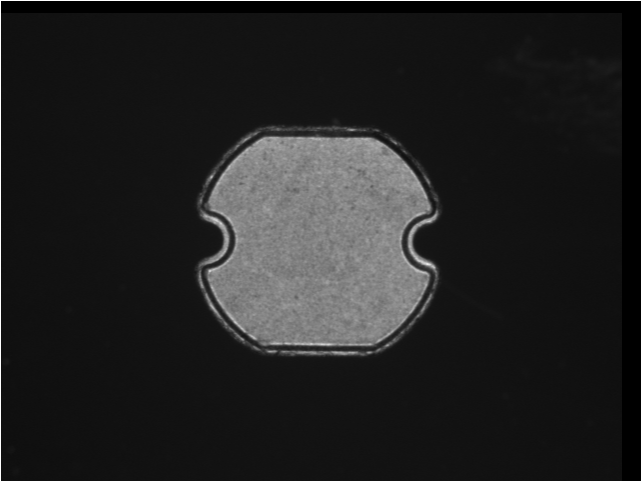

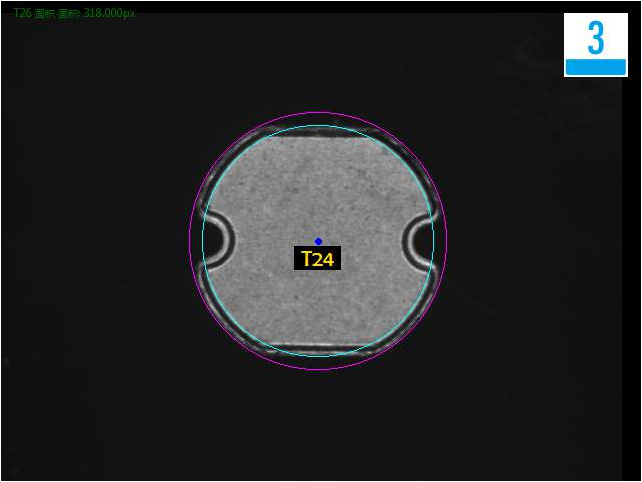

With a team of experienced R&D professionals and industrial automation engineers, Sipotek Technology designs and develops visual inspection machines to check the flaws of a product in an automated manner. These machines come fitted with industrial cameras to capture images of a product. These images can then be matched with the template to detect any kind of quality defects or missing components. These machines are easy to operate and require low maintenance.

For manufacturing companies, using a Sipotek Visual Inspection Machine could be a good idea to perform inspections at every stage of the manufacturing process. In comparison to the manual inspections, the visual machine based inspections are more accurate and reliable. They have the simple one-click detection machine that is a compact desktop model to carry out quality tests. This fast and efficient equipment can perform batch testing in just 2 seconds. With a significantly reduced measurement time, this machine could be an ideal choice for a rapid detection of multiple products. The machine has a simple operation without any movement of the platform. It can automatically match the captured image with the template to detect the good or bad products. The software of the machine can reduce the human error.

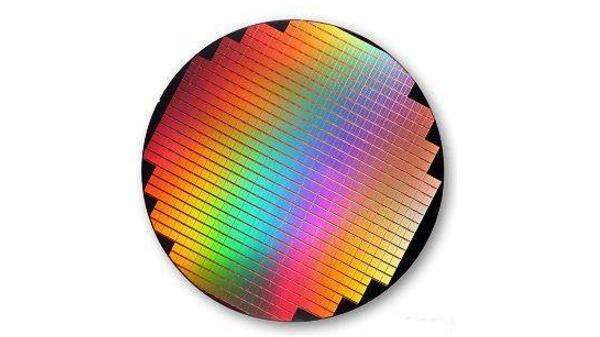

The company spokesperson especially mentions about their automated optical inspection machine that has been designed to perform a visual inspection of printed circuit boards. The machine can perform a non-contact testing and is more suitable for automating the manufacturing process. Besides checking for the quality defects, this machine can also find out missing components of a product and can avoid its chances of a catastrophic failure. The spokesperson reveals that this machine is the best choice to be implemented in the various stages of the manufacturing process to carry out inspections, such as pre-reflow and post-reflow inspections, solder paste inspections and others. With its capacity of capturing images at a speedy rate, this automated inspection machine can also be used for barcode reading, character recognition and other purposes, besides carrying out the inspections.

Sipotek Technology boasts of a number of visual inspection machines in its portfolio. These machines come fitted with industrial cameras and by using advanced lighting and optical technologies, the quality checking task is performed in the most efficient manner. The spokesperson reveals that these machines can be programmed for checking a wide variety of parts. At the same time, they are capable of inspecting various materials, such as aluminum, plastic, rubber, stainless steel and others. The visual inspection machines consist of image storage, data collection and analysis, total part counters and other features.

To know more about the features and specifications of the visual inspection machines developed by the company, one can visit the website https://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Pinterest:https://www.pinterest.com/chinasipotek/

Website: https://www.sipotek.net