Inductance Detection Scheme Shenzhen SPOTECK Technology Co., Ltd.

SPOTECK has been focusing on machine vision inspection for 13 years

For product appearance size, defects, defects, scratches, stains, burrs and other detection

There are countless test cases. Welcome to inquire and get the test plan free of charge.

1. Contents and requirements of testing

Measure workpiece area:

Inspection of bottom appearance, top appearance and size of inductance sample

Content of detection:

1: Detect the damage and notch on the bottom.

2. Side detection of height and width.

2. Top surface inspection for breakage and notch.

Note: The above detection items need to be clearly visible under the image to detect.

Detection efficiency: 300-450 pieces per minute (according to sample feeding speed).

Division of work: Subdivide the detection steps according to the detection content.

II. Equipment Composition and Major Institutions

Overall Composition: Dimension: 900*800*1850 mm

Model: SP_302C

1:SPOTECK Visual Detection Software

2: industrial computer

3: display 19 inches

4: Industrial cameras: 3 sets, bottom detection, side detection, top detection

5: Industrial lens: 2 FA industrial lens, 1 telecentric lens

6: professional glass tray

7: solenoid valve

8: reducer

9: vibration cabinet

10: Feeding equipment (Vibrating disc, Direct Vibration, Controller).

II.1: 3-D Stereogram of Equipment Appearance

3:1 Bottom Testing Hole Mode

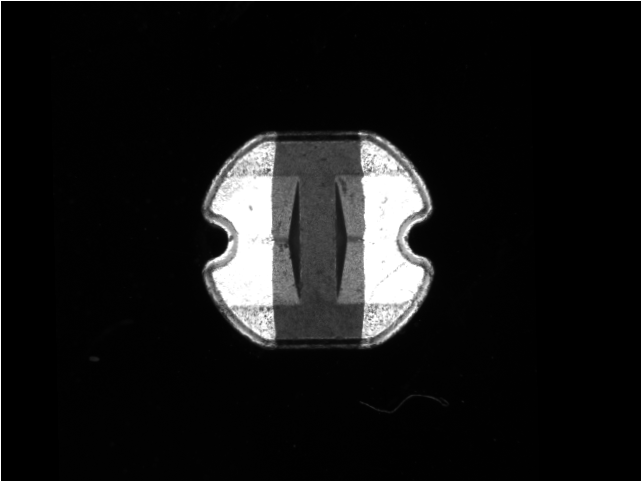

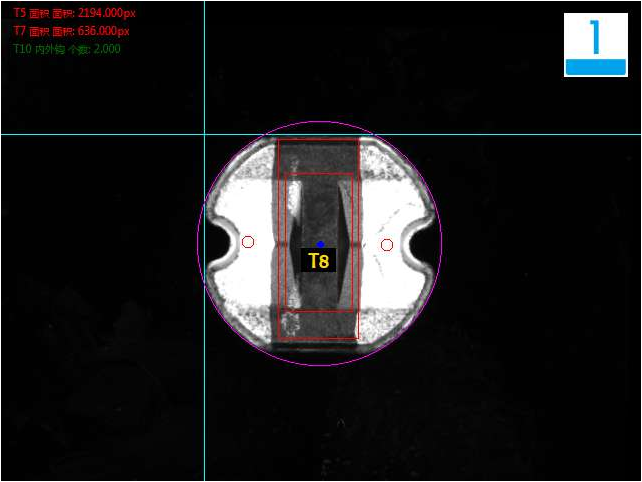

The original picture of bottom detection effect:

3:1 Bottom Testing Hole Mode

Bottom Test Fine Product Analysis Chart: OK

3:1 Bottom Testing Hole Mode

Underprint negative result map: NG

3:1 Bottom Testing Hole Mode

Bottom detection result chart: NG

3:1 Bottom Testing Hole Mode

Bottom detection result chart: NG

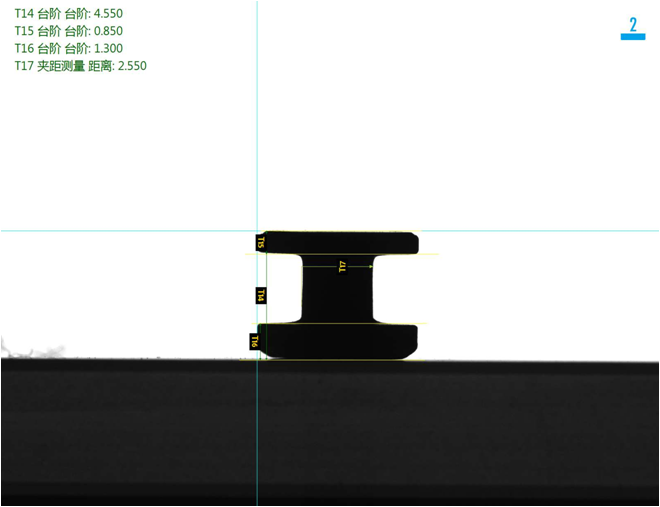

3:2 Side Detection Method

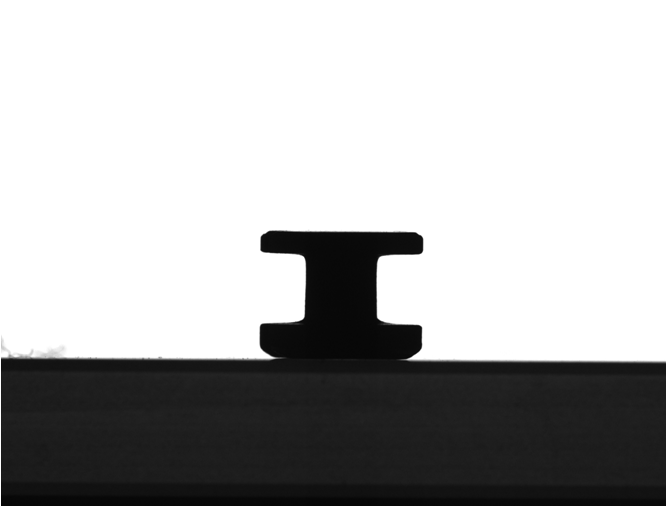

The original image of side detection effect:

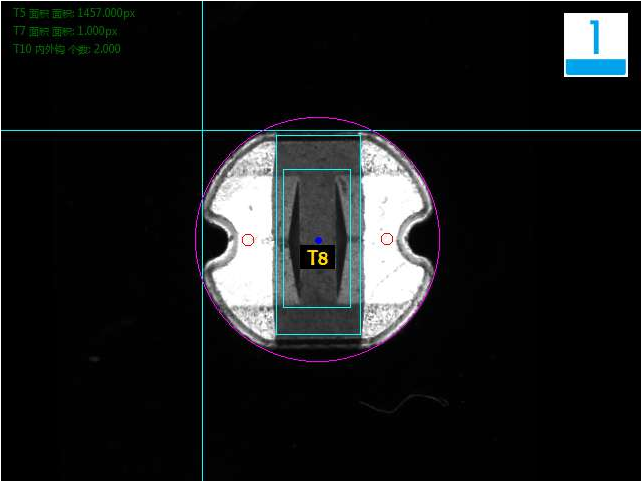

3:2 Side Detection Method

Analysis Chart of Fine Products for Side Detection: OK

3:3 Top Detection Method

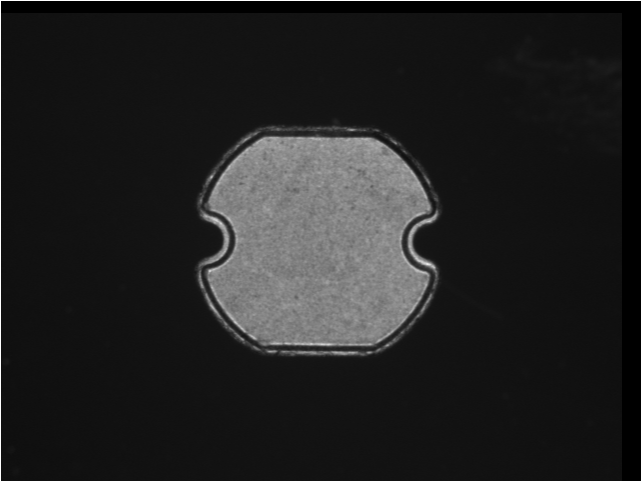

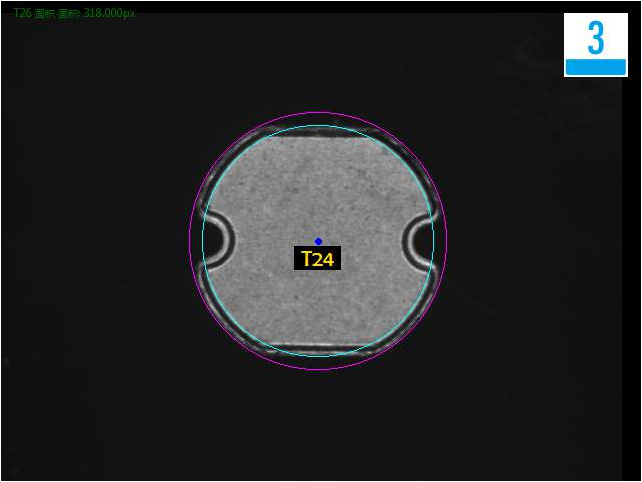

Top detection effect original picture:

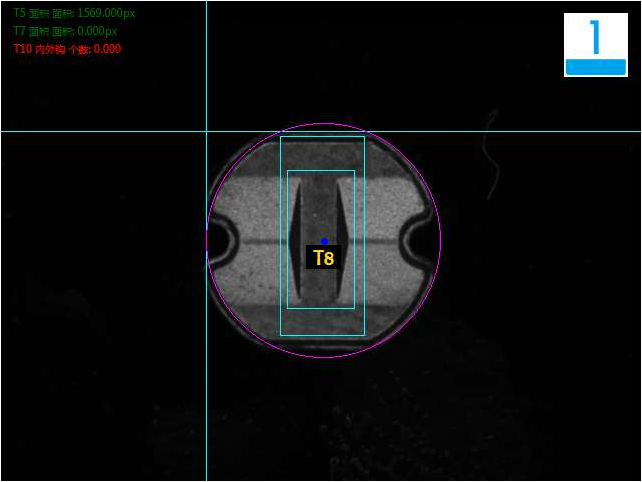

3:3 Top Detection Method

Top test product analysis chart: OK

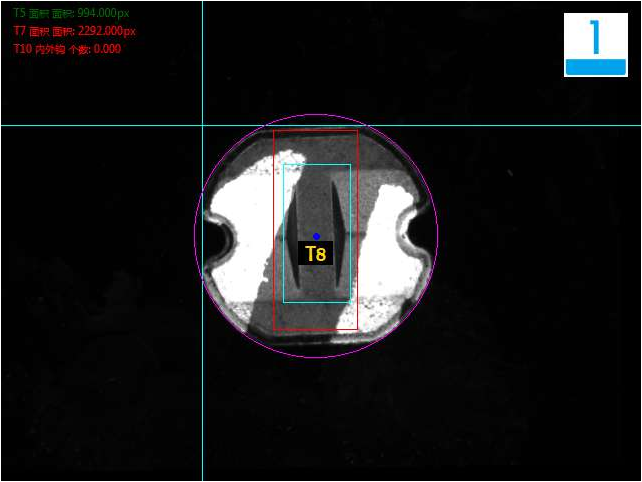

3:3 Top Detection Hole Mode

Top Detection Print Anti-Bad Result Diagram:NG

IV. System Installation Requirements:

Inspection space for equipment placement: Separately installing SP visual inspection system at the pipeline side, it is necessary to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic jamming: Provide equipment with less electronic jamming.

Power supply: 220V, 50Hz AC, less than 1KVA power consumption

Article Original From:https://www.sipotek.net/inductance-detection-scheme/

Decent post, noteworthy through hole AOI machine. It's very not the same as different posts. Much obliged for sharing.

回复删除