1. Contents and requirements of testing

Measure workpiece area:

Size and Appearance Testing of Samples with Inner Diameter of 10mm*Thickness of 2mm

Content of detection:

1: bottom appearance

2: side height

3: top appearance

4: Maximum diameter, minimum diameter, burr

Note: The above detection items need to be clearly visible under the image to detect.

Detection efficiency: 180-250 pieces per minute (according to sample feeding speed).

Division of work: Subdivide the detection steps according to the detection content.

II. Equipment Composition and Major Institutions

Overall Composition: Dimension: 900*800*1850 mm

Model: SP_302C

1:SPOTECK Visual Detection Software

2: industrial computer

3: display 19 inches

4: Industrial cameras: 4 sets, respectively, bottom positive light, side back light, top positive light, top back light.

5: Industrial lens: 2 FA industrial lens, 2 telecentric lens

6: professional glass tray

7: solenoid valve

8: reducer

9: vibration cabinet

10: Feeding equipment (Vibrating disc, Direct Vibration, Controller).

II.1: 3-D Stereogram of Equipment Appearance

3:1 Bottom Detection Method

Bottom detection effect original picture:

3:1 Bottom Detection Method

Bottom Test Fine Product Analysis Chart: OK

3:1 Bottom Detection Method

Bottom Detection Fracture Failure Analysis Diagram:NG

3:1 Bottom Detection Method

Bottom defect analysis chart:NG

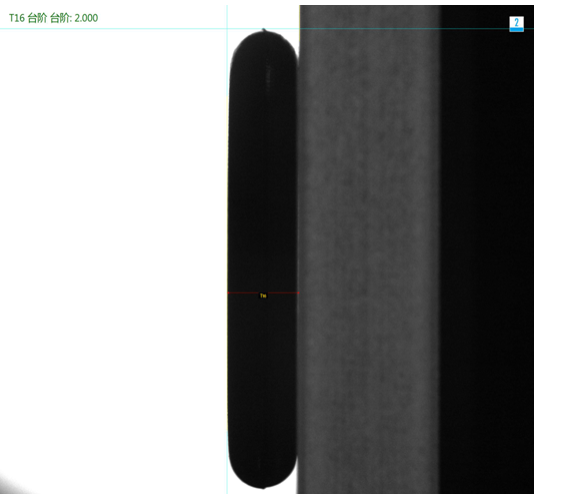

3:2 Side Detection Method

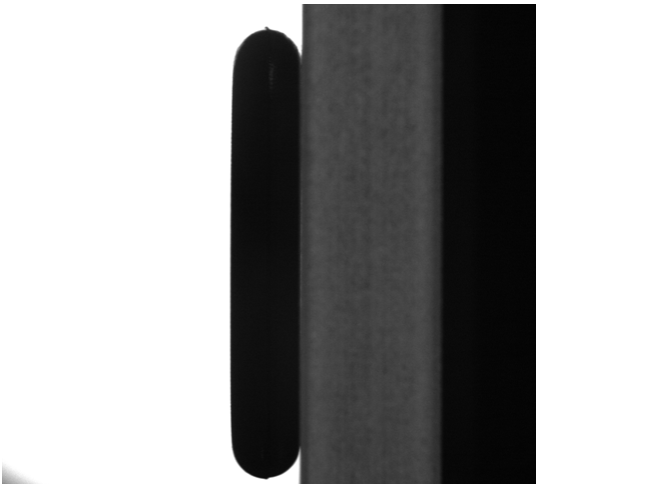

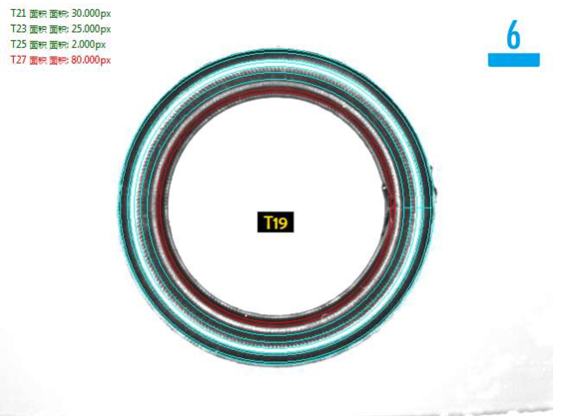

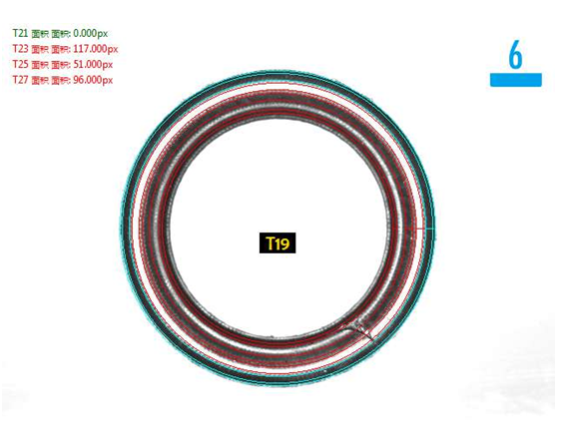

The original image of side detection effect:

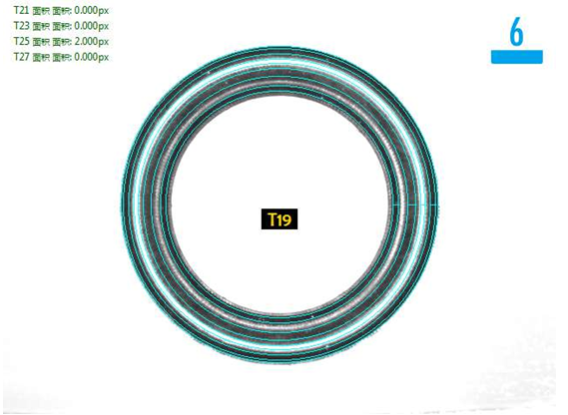

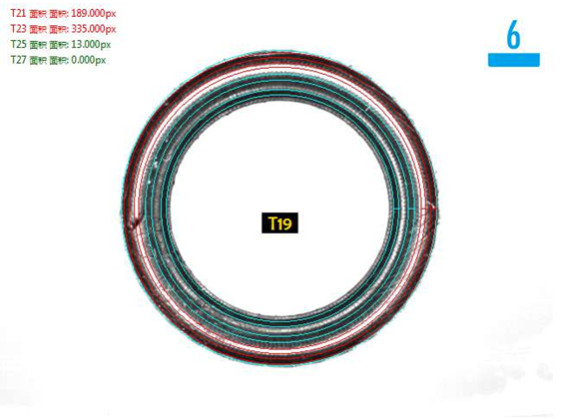

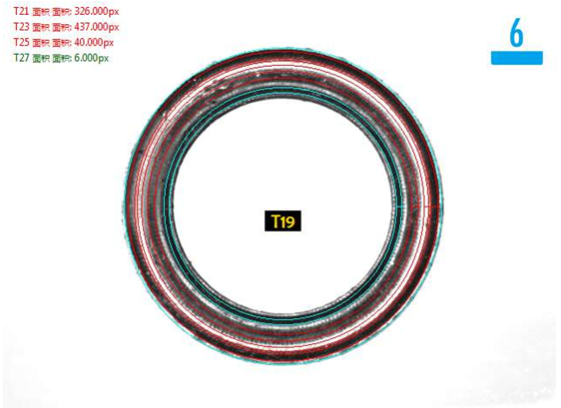

3:2 Side Detection Method

Analysis of the effect of side detection products: OK

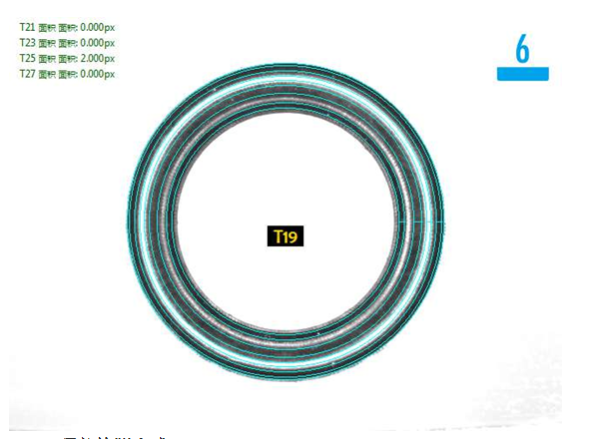

3:3 Top Detection Method

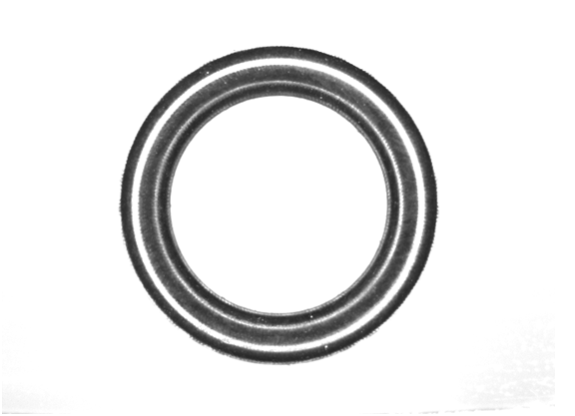

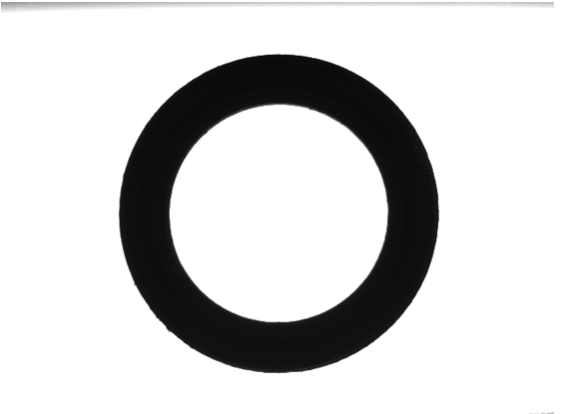

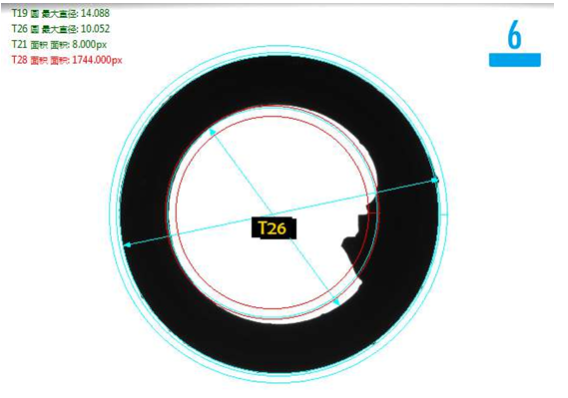

Top detection effect original picture:

3:3 Top Detection Method

Top test product analysis chart: OK

3:3 Top Detection Method

Negative Analysis Chart of Top Detection Lack of Material:NG

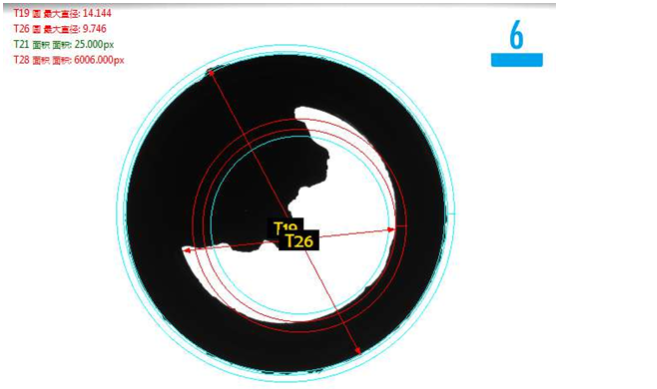

3:3 Top Detection Method

Top Detection Fracture Analysis Diagram: NG

3:3 Top Detection Method

Top Detection Fracture Analysis Diagram: NG

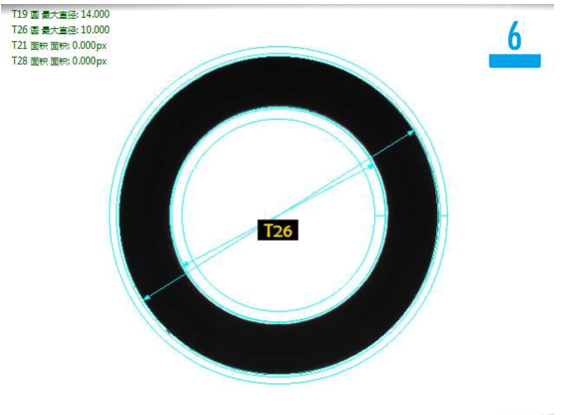

3:4 Top Backlight Detection Method

Top Backlight Test Fine Product Analysis Chart: OK

3:4 Top Backlight Detection Method

Top Detected Edge Bad Analysis Chart:NG

3:4 Top Backlight Detection Method

Top Detected Edge Bad Analysis Chart:NG

IV. System Installation Requirements:

Inspection space for equipment placement: Separately installing SP visual inspection system at the pipeline side, it is necessary to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic jamming: Provide equipment with less electronic jamming.

Power supply: 220V, 50Hz AC, less than 1KVA power consumption

Article Original From:https://www.sipotek.net/machine-vision-inspection-scheme-for-o-ring/

没有评论:

发表评论